|

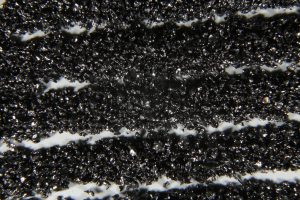

Manufactured from the highest quality raw materials to bring you the best performance in open nozzle blasting |

|

|

Mohs hardness of 7-8 which ensures fast easy removal of rust, millscale and old paint coatings from steel to the highest standards of cleanliness (Sa3)

Durable

Low shatter index ensures efficient energy transfer to the worksurface. Scangrit Iron Silicate is able to clean without excessive particle breakdown so reducing the quantity of dust generated during blasting.

Fast

Sharp cutting edges rapidly remove paint, corrosion, and millscale. Scangrit Grade 3 is capable of cleaning to Sa2.5 and rates of up to 10- 12 m/h

Clean

A unique fuming process removes lead and other heavy metals to very low levels. The lead content is less than 0.04% for Grades 2, 3, and 4.

Water soluble chloride and other salts are well below the levels prescribed by ISO 11126-3.

Low dust

Scangrit Iron silicate abrasives are air-washed to remove dust and fines, typical dust content of Scangrit Grade 3 is less than 1% below 212 microns. ISO standards permit up to 5% below 200microns.

Standard Grades

| Grade | Size Range | Profile* |

Application |

| 1 | 0.1 – 0.4mm | Less than fine | Cleaning surfaces where low profile is required. Suitable for the restoration of classic cars and motor bikes |

| 2 | 0.2 – 0.85mm | Fine | To provide a fine profile for low build paints, selective removal of coatings and wet blasting. Also suitable for small nozzle work and hand guns. |

| 3 | 0.2 – 1.70mm | Medium | Specially graded to rapidly clean steelwork to Sa2.5 and Sa3 with a medium profile to suit the majority of industrial coatings. Suitable for ships hulls, tanks, storage vessel bridges and steel fabrications |

| 4 | 0.5 – 2.0mm |

Coarse | To provide coarser profile suitable for metal spray. |

| 5 | 0.2 – 2.50mm | Coarse | Highly corroded steel. |

| 6 | 0.5 – 2.50mm | Coarse | Removal of heavy scale. To provide very coarse profile for rubber lining, etc… |

* Surface profile achieved on mild steel (BS EN ISO 8503)